Traditional Fungal Foods

Nowaday interest in traditional fermentation technology for food processing has greatly increased because of emphasis placed upon plant materials as human foods. Most of the fermentation processes were developed in ancient time before the recognition for existence of microorganisms (Wang and Hesseltine, 1981). How surprising! the early man developed the methods and maintained the cultures through the centuries without having the concept of microorganisms. Nowadays, these foods are an important component of daily diets of many of the world's population especially in Japan, Indonesia, India, Pakistan, Thailand, Phillippines, Taiwan, Korea, China and encompassing areas and part of Africa.

These Foods were produced long before the written history. Though production of shoyu, miso and sake was being practiced for the ancient time, yet it gained additional impetus with the spread of Buddhism (635 BC-550 AD) which favored the vegetarian diet and taught the sanctity of all life. That is why this concept has fostered the more widespread consumption of sauces and pastes such as shoyu and miso that provide meaty flavor. The first scientific report on application of oriental fermentation to modern industrial process are about 100 years old. Between 1878 -1914 a number of fermented foods and drinks, and isolation of microorganisms were done. Studies of these could not be strengthened due to World War I and II; the same could be resumed in 1950s. However, these techniques could be industrialized in recent years and many more fermented foods are produced at village level also. Some of the oriental fermented foods, substrates and cultures of microorganisms are given in Table 18.4.

Some times it becomes problematic if there is presence of toxins in oriental fermented fungal food. Biotechnological hazards of mycotoxins have been discussed in

Secondary Metabolites. However, more than 73 strains of

Aspergillus including

A. oryzae, A. niger, A. usami, etc. have been isolated from oriental fermented fungal foods. In some samples, as such no aflatoxins were found in foods, but 30 per cent of these strains produced compounds that were very similar to those of aflatoxins in fluorescent spectra of Rf value in thin layer of chromatograms. These fluorescent compounds were found most toxic. Some strains have been found to produce aspergillic acid. In Koji fermentation b-nitropropionic acid was produced by one of the strains.

A. flavus or

A. parasiticus contaminated culture of

A. oryzae used for preparation of soy sauce has been found to produce aflatoxin. Therefore, precautions should be taken while inoculation done. The preparation of food by fermentation has certain advantages. Fermentation produces certain enzymes, destroys or makes undesirable flavor and odors, adds flavor, preserves food, synthesizes desirable constituents such as vitamins and antibiotics, increases digestibility, changes physical states, produces color and reduces cooking time. The properly fermented foods are non-hazardous to health.

Table. 18.4. Traditional fermented foods, substrates and microorganisms used for production.

| Food/country |

Substrates |

Microorganism |

| Dosa/India |

Rice, dehulled black gram |

Yeast, Leuconostoc mesenteroides |

| Idli/ India |

Rice, dehulled black gram |

Yeast, Leuconostoc mesenteroides |

| Laochao/China, Indonesia |

Waxy variety of rice |

Amylomyces rouxii NRRL3160, Rhizopus chinensis, R. oryzae |

| Miso/ Japan, China, |

Whole soybean, rice or barley |

Asperqillus oryzae NRRL5593, Saccharomyces rouxiii |

| Mahewu / S. Africa |

Maize |

Lactobacillus delbrueckii |

| Natto/ Japan |

Whole soybeans |

Bacillus natto (= B. subtilis) |

| Ontjam / Indonesia |

Peanut pres.s cake |

Neurospora intermedia NRRL6025 |

| Shoyu (soy sauce)/Japan, China |

Wheat, soybeans |

A. oryzae, A. sojae |

| Sufu(fu-ru) / China |

Soybean curd (tofu) |

Actinomucor elegans, Mucor disperses |

| Tempe/Indonesia |

Whole soybeans |

Rhizopus oligosporus NRRL2710 |

Source : Wang and Hesseltine (1981); Hesseltine (1983).

Shoyu (soy sauce)Shoyu is a Japanese term which denotes its preparation by fermentation not by chemical treatments .of soybeans. It was applied thousands of years ago. Historically, 'sho' or 'misho' refers to animal sauces which were first made from salted marine animals as well as meat from wild game. These terms were developed probably later to denote the 'meaty flavored' vegetarian sauces (Yokotsuka, 1960). The term koji refers to any substrates overgrown with filamentous fungus and used as a source of enzymes.

The Japanese Agricultural Standard defines five types of shoyu of which koikuchi types represents 85 per cent of all the shoyu consumed in Japan.

Koji is prepared by roasting wheat at 170 -180°C for a few minutes and finally coarsely crushing into 4-6 pieces. Soybeans (seeds or defatted soybean grits) are soaked in water for 15 h and autoclaved for 1 h (Fig. 18.3). Crushed wheat and autoclaved soybeans are mixed properly so that the surface of soybeans could be coated with ground wheat. Finally, it is inoculated with seed culture

{Aspergillus oryzae or

A. sojae). Wheat provides nutrients to the fungus to grow well on the surface of soybeans. In Japanese shoyu, nearly equal amount of soybean and wheat are used, whereas in Chinese shoyu the amount of wheat remains low.

Koji fermentation is carried out on a large perforated stainless steel plate (5 x 12 m) for 2-3 days. Proper temperature (30°C) and moisture (40-43 per cent) are maintained during this period. The koji is overgrown by the fungus. This facilitates to produce desirable enzymes. Now, koji is mixed with salt water (22-23 per cent salt, w/v) to make mash, the 'moromi'. The mash is transferred to deep fermentation tank (50-300 kilolitre capacity) and held for 4-8 months, depending on temperature, with occasional air compressing. It is agitated at certain intervals. These promote microbial growth. At this time the fungus is killed but its enzymes hydrolase about 10 per cent soybean proteins to amino acids and low molecular weight peptides. About 20 per cent of wheat starch is used by the fungus, and the remaining is converted to simple sugars. One half of sugars is converted first to lactic acid by

Pediococcus halophilus (lactobacillus) and then into alcohol by yeast

(S. rouxii) (Hesseltine, 1983). Finally, liquid is pasteurized and packed. Shoyu is packed in bottles in Japan, and preserved with sodium benzoate in China.

MisoMiso is similar to peanut; it is light yellow to black in color. It is used as soup base and also to add flavor to foods such as fish, vegetables and meat. On the basis of substrate miso is grouped into three :

(i) rice miso (made from rice, soybean and salt),

(ii) barley miso (made from barley, soybeans and salt), and

(Hi) soybean miso (made from soybeans and salt). In miso preparation, whole soybean (not defatted soybean flakes ) is used because the defatted soybean flakes are to give an inferior product (Hesseltine, 1983).

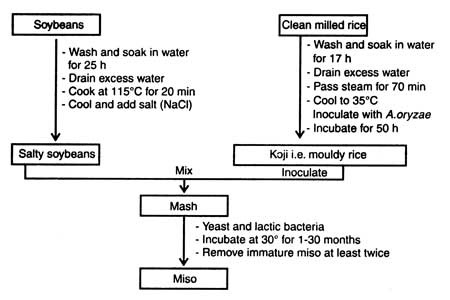

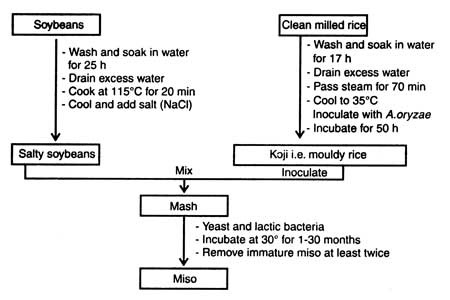

Soybeans are washed, soaked in water (for 17 h) and cooked (at 115°C for 20 min) (Fig. 18.4). When cooled, soybeans are added with NaCl. Koji is made from clean milled rice after soaking in water and passing through steam is an open cooker for 40 min. When cooled down, rice in sprayed with dry spores of A.

oryzae or

A. sojae (at the rate of 1 g inoculum (10

9 viable spores)/kg of raw rice). Koji is incubated for about 50 h in fermenters. The fungus consumes about 10 per cent of the rice. The salty soybeans are mixed . The salt kills the fungus. Unlike shoyu, no water is added, therefore, the fermenting mash is a thick paste. While mashing, pure culture of yeast

(Saccharomyces rowcii) and lactic bacteria

(Pediococcus halophillus) is added. It is allowed to ferment at 30°C for 1-3 months depending on miso types desired. In this case mash is a. paste, so it cannot be agitated but early produced miso is removed at least twice to improve fermentation. The final product, miso, is obtained. In the final product 60 per cent of protein including amino acids and peptides is water soluble, and 75 per cent carbohydrate is reducing sugar (Hesseltine, 1983). Miso is becoming an important food among the vegetarians in the United States because of its varying variety of flavors

i.e. sweet, salty and meaty.

Sake

By fifth century A.D., sake brewing was well established in Japan and became the traditional drink (Kodama and Yoshizawa, 1977). Since then several refinements have been done time to time.

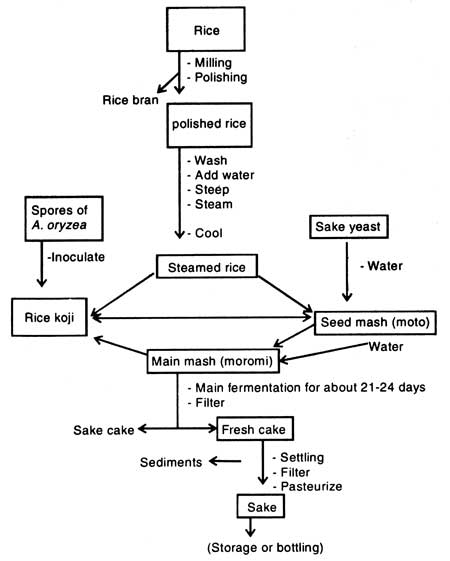

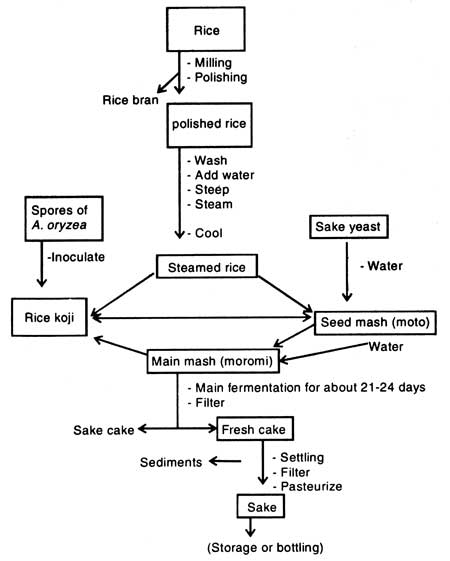

Rice is milled and polished which, after washing and steeping, is steamed for 20-30 minutes (Fig. 18.5).

Fig. 18.3. Outline of koikuchi shoyu fermentation (after Yokotsuka, 1981)

Fig. 18.4. Outline for production of Japanese rice miso (based on Hesseltine, 1983).

Fig. 18.5. Outline of brewing process of Japanese sake (after Kodama and Yoku, 1977).

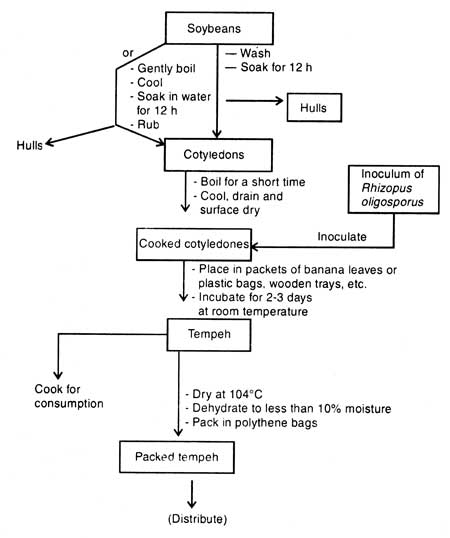

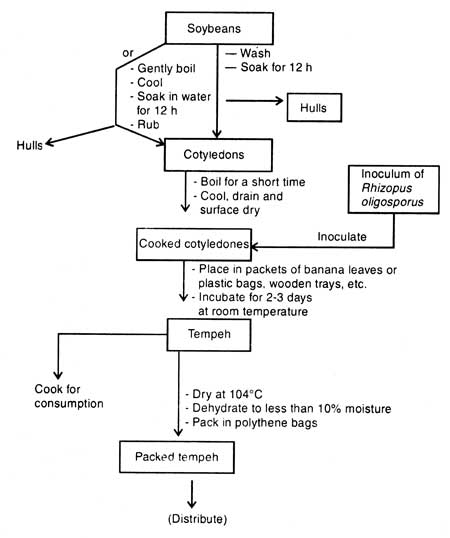

Fig, 18.6. Outline of tempeh production in Indonesia (based on Steikraus, 1983).

The steamed rice is cooled to about 35°C and mixed to get even temperature and moisture. The steamed rice is inoculated with spores of

A. oryzae and mixed well. Koji is distributed in boxes having wire mesh bottom to control the temperature and moisture. The boxes are incubated for 40h. When temperature reaches to 40-42° it favors for optimum amylolytic activity of the fungus. Fermentation of starch occurs. Koji is spread over clean cloths to lower the temperature until used for mashing. The Koji mould brings about saccharification of rice starch resulting in production of sugar. The koji is mixed with water, steamed rice and sake yeast

(S. sake; syn.

S. cerevisiae) culture. It is called as yeast seed mash or 'moto’. It is a pure yeast culture to be used as starter inoculum for main fermentation. The yeast seed mash, koji and water are mixed to get fresh sake, the main mash or ‘moromi’ Fermentation of main mash is done for about three weeks. Sugars formed by koji fungus is fermented to alcohol by the sake yeast. Therefore, it is filtered to get fresh sake. It is again filtered, pasteurized and bottled or stored as desired. Imayasu (1972) has described the following four characteristics of sake:

(i) In Japan, sake preparation is based on fermentation of nonglutinous rice, whereas elsewhere in Asia, it is made from glutinous rice.

(ii) Koji is used for saccharification.

(iii) Saccharification and fermentation occur at the same time,

(iv) Sake has the highest amino acid content of all alcoholic drinks. Amino acids come from the enzymatic digestion of rice proteins by the mould enzyme.

Tempeh

Tempeh is a traditional meat analogue of Indonesia. It is a white and mouldy cake produced by fungal fermentation of soaked, dehulled, hydrated and partially cooked soybean cotyledons. It can be sliced and fried in fat or cut into pieces, and used as a protein rich meat analogue.

Soybeans are washed and soaked for 12h. During this period it undergoes bacterial acid fermentation. Consequently, pH is lowered to 5 or bellow. The other method is to bring the soybeans to boil and then soak in water for about 12h. This helps to dehull the soybeans. Soybeans are rubbed gently. The hulls float on water surface from where they are removed. The cotyledons are boiled for a very short time to get them artificially cooked. They are drained, cooled, surface dried and inoculated with pure culture of

Rihzopus oligosporus. The cotyledons are inoculated before or after placing them in fermentation containers. Traditionally, the inoculated cotyledons are wrapped in small pockets made of wilted banana leaves or other large leaves (Fig. 18.6). These packets are incubated in a warm place for 2-3 days (Steinkraus, 1983).

But for a few years, the commercial tempeh industry in Indonesia has adopted wooden trays (35 x 80 x 1.3 cm). The inoculated cotyledones are also placed in perforated plastic bags, plastic tubes, etc. The wooden trays are lined with perforated plastic sheets. The perforations allow the exchange of gases. These bags are incubated at 30-37°C with high moisture contents. Fungal mycelium grows well and completely covers the cotyledons. It is ready for cooking. Also, it is dried at 104°C and dehydrated to less than 10 per cent moisture and packed in polythene bags. During fermentation, proteins are partially hydrolyzed, lipids are hydrolyzed, riboflavin doubles and niacin increases 7 times (Steinkraus, 1983).

In addition to meaty flavor and source of protein, tempe is also known to prevent bacterial infection of intestine.

R.oligosporus is an antibacterial agent active against

Streptococcus, Leuconostoc, Staphylococcus aureus, Bacillus, Clostridium (Hesseltine, 1985).