Eli Whitney, Jr.

Contents

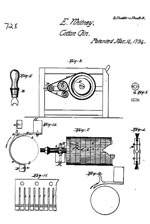

Early lifeWhitney was born in Westborough, Massachusetts, on December 8, 1765, the eldest child of Eli Whitney Sr., a prosperous farmer and his mother, Elizabeth Fay of Westborough, who died when he was eleven. At age fourteen he operated a profitable nail manufacturing operation in his father's workshop during the Revolutionary War. Because his stepmother opposed his wish to attend college, Whitney worked as a farm laborer and schoolteacher to save money. He prepared for Yale at Leicester Academy (now Becker College) and under the tutelage of Rev.Elizur Goodrich of Durham, Connecticut he entered the Class of 1789.Whitney expected to study law but, finding himself short of funds, accepted an offer to go to South Carolina as a private tutor. Instead of reaching his destination, he was convinced to visit Georgia. In the closing years of the eighteenth century, Georgia was a magnet for New Englanders seeking their fortunes (its Revolutionary era governor had been Lyman Hall, a migrant from Connecticut). When he initially sailed for South Carolina, among his shipmates were the widow and family of Revolutionary hero, General Nathanael Greene of Rhode Island. Mrs. Greene invited Whitney to visit her Georgia plantation, Mulberry Grove. Her plantation manager and husband-to-be was Phineas Miller, another Connecticut migrant and Yale graduate (Class of 1785), who would become Whitney's business partner. Whitney is most famous for two innovations which later divided the United States in the mid-19th century: the cotton gin (1793), and his advocacy of interchangeable parts. In the South, the cotton gin revolutionized the way cotton was harvested and reinvigorated slavery. While in the North, the adoption of interchangeable parts revolutionized the manufacturing industry, and in time contributed greatly to their victory in the Civil War. Career inventionsInterchangeable partsThough Whitney is popularly credited with the invention of a musket that could be manufactured with interchangeable parts, the idea predated him. The idea is credited to Jean Baptiste Vaquette de Gribeauval, a French artillerist, and credits for finally perfecting the "armory system," or American system of manufacturing, is given by historian Merritt Roe Smith to Captain John H. Hall and by historian Diana Muir writing in Reflections in Bullough's Pond to Simeon North. In From the American System to Mass Production, historian David A. Hounshell described how de Gribeauval's idea propagated from France to the colonies via two routes: from Honoré Blanc through his friend Thomas Jefferson, and via Major Louis de Tousard, another French artillerist who was instrumental in establishing West Point, teaching the young officer corps of the Continental Army, and establishing the armories at Springfield and Harpers Ferry. By the late 1790s, Whitney was on the verge of bankruptcy and cotton gin litigation had left him deeply in debt. His New Haven cotton gin factory had burned to the ground, and litigation sapped his remaining resources. The French Revolution had ignited new conflicts between Great Britain, France, and the United States. The new American government, realizing the need to prepare for war, began to rearm. The War Department issued contracts for the manufacture of 10,000 muskets. Whitney, who had never made a gun in his life, obtained a contract in January, 1798 to deliver ten to fifteen thousand muskets in 1800. He had not mentioned interchangeable parts at that time. Ten months later, Treasury Secretary Wolcott sent him a "foreign pamphlet on arms manufacturing techniques," possibly one of Honoré Blanc's reports, after which Whitney first began to talk about interchangeability. After spending most of 1799-1801 in cotton gin litigation, Whitney began promoting the idea of interchangeable parts, and even arranged a public demonstration of the concept in order to gain time. He did not deliver on the contract until 1809, but then spent the rest of his life publicizing the idea of interchangeability. Whitney's defenders have claimed that he invented the American system of manufacturing -- the combination of power machinery, interchangeable parts, and division of labor that would underlie the nation's subsequent industrial revolution. While there is persuasive evidence that he failed to achieve interchangeability, his use of power machinery and specialized division of labor are well documented . When the government complained that Whitney's price per musket compared unfavorably with those produced in government armories, Whitney was able to calculate an actual price per musket by including fixed costs such as insurance and machinery, which the government had not included. He thus made early contributions to both the concept of cost accounting, and the concept of the efficiency of private industry. Cotton gin The cotton gin is a mechanical device which removes the seeds from cotton, a process which, until the time of its invention, had been extremely labor-intensive. The cotton gin was a wooden drum stuck with hooks, which pulled the cotton fibers through a mesh. The cotton seeds would not fit through the mesh and fell outside. Whitney occasionally told a story where he was pondering an improved method of seeding the cotton and he was inspired by observing a cat attempting to pull a chicken through a fence, and could only pull through some of the feathers. A single cotton gin could generate up to fifty-five pounds of cleaned cotton daily. This contributed to the economic development of the Southern states of the United States, a prime cotton growing area; some historians believe that this invention allowed for the African slavery system in the Southern United States to become more sustainable at a critical point in its development. Milling machine Machine tool historian Joseph W. Roe credited Eli Whitney with inventing the first milling machine. Subsequent work by other historians (Woodbury, Smith, Muir) suggests that Whitney was among a group of contemporaries all developing milling machines at about the same time (1814 to 1818). Therefore, no one person can properly be described as "the inventor of the milling machine". Later life and legacyDespite his humble origins, Whitney was keenly aware of the value of social and political connections. In building his arms business, he took full advantage of the access that his status as a Yale alumnus gave him to other well-placed graduates, such as Secretary of War Oliver Wolcott (Class of 1778) and New Haven developer and political leader James Hillhouse. His 1817 marriage to Henrietta Edwards, granddaughter of the famed evangelist Jonathan Edwards, daughter of Pierpont Edwards, head of the Democratic Party in Connecticut, and first cousin of Yale's president, Timothy Dwight, the state's leading Federalist, further tied him to Connecticut's ruling elite. In a business dependent on government contracts, such connections were essential to success.

Whitney died at age 59 of prostate cancer on January 8, 1825, in New Haven, CT, leaving a widow and four children. During the course of his illness, he invented and constructed several devices to ease his pain mechanically. These devices, drawings of which are in his collected papers, were effective but were never manufactured for use of others due to his heirs' reluctance to trade in "indelicate" items. At his death, his armory was left in the charge of his talented nephews, Eli Whitney Blake and Philos Blake, notable inventors and manufacturers in their own right (they invented the mortise lock and the stone-crushing machine). Eli Whitney Blake (1820-1894) assumed control of the armory in 1841. Working under contract to inventor Samuel Colt, the younger Whitney manufactured the famous "Whitneyville Walker Colts" for the Texas Rangers. The success of this contract rescued Colt from financial ruin and enabled him to establish his own famous arms company. Whitney's marriage to Sarah Dalliba, daughter of the U.S. Army's chief of ordinance, helped to assure the continuing success of his business. The younger Whitney organized the New Haven Water Company, which began operations in 1862. While this enterprise addressed the city's need for water, it also enabled Whitney to increase the amount of power available for his manufacturing operations at the expense of the water company's stockholders. A new dam made it possible to consolidate his operations - originally located in three sites along the Mill River - in a single plant. This dam still exists. Whitney's grandson, Eli Whitney IV (1847-1924), sold the Whitney Armory to Winchester Repeating Arms, another notable New Haven gun company, in 1888. He served as president of the water company until his death and was a major New Haven business and civic leader. He played an important role in the development of New Haven's Ronan-Edgehill Neighborhood. Following the closure of the armory, the factory site continued to be used for a variety of industrial purposes, including the water company. Many of the original armory buildings remained intact until the 1960s. In the 1970s, as part of the Bicentennial celebration, interested citizens organized the Eli Whitney Museum, which opened to the public in 1984. The site today includes the boarding house and barn that served Eli Whitney's original workers and a stone storage building from the original armory. Museum exhibits and programs are housed in a factory building constructed c. 1910. A water company office building constructed in the 1880s now houses educational programs operated by the South Central Connecticut Regional Water Authority (which succeeded the New Haven Water Company). Eli Whitney and his descendants are buried in New Haven's historic Grove Street Cemetery. Yale College's Eli Whitney Students Program, which is one of the four doors into Yale College, is named after Whitney in recognition of his venerable age at the time of his entrance to Yale College in 1789; he was twenty-three years old. Further reading- Battison, Edwin. (1960). "Eli Whitney and the Milling Machine." Smithsonian Journal of History I.- Cooper, Carolyn, & Lindsay, Merrill K. (1980). Eli Whitney and the Whitney Armory. - Whitneyville, CT: Eli Whitney Museum. - Dexter, Franklin B. (1911). "Eli Whitney." Yale Biographies and Annals, 1792-1805. New York, NY: Henry Holt & Company. - Hall, Karyl Lee Kibler, & Cooper, Carolyn. (1984). Windows on the Works: Industry on the Eli Whitney Site, 1798-1979. - Hamden, CT: Eli Whitney Museum - Hounshell, David A. (1984), From the American system to mass production, 1800-1932: The development of manufacturing technology in the United States, Baltimore, Maryland, USA: Johns Hopkins University Press. - Lakwete, Angela. (2004). Inventing the Cotton Gin: Machine and Myth in Antebellum America. Baltimore, MD: Johns Hopkins University Press. - Smith, Merritt Roe. 1973. "John H. Hall, Simeon North, and the Milling Machine: The Nature of Innovation among Antebellum Arms Makers." Technology & Culture 14. - Woodbury, Robert S. (1960). "The Legend of Eli Whitney and Interchangeable Parts." Technology & Culture 1. |

|||||||||||||||||||||||||||||||||||||||||||||||||