Compost ingredients

Content

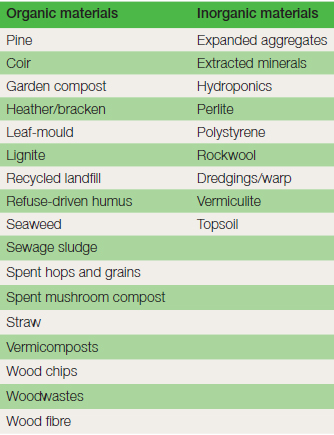

Over the years growers have added a wide variety of materials, such as leaf mould, pine needles, spent hops, old mortar, crushed bricks, composted animal and plant residues, peat, sand and grit, to selected soils to produce a compost with suitable physical properties. To supplement the nutrient released from the materials in the compost, if any, various slow release organic manures or small dressings of powdered soluble inorganic fertilizers have been added to the mixtures to provide the necessary nutrition. The correct physical and nutritional conditions are vital to successful growing in a restricted rooting volume. Significant developments occurred as a result of the work done in the 1930s at the John Innes Institute, where the importance of ‘sterile’ (pest and disease free), stable and uniform ingredients was demonstrated. The range of composts that resulted from this work established the methods of achieving uniform production and reliable results with a single potting mixture suitable for a wide range of plant species. Loam composts Loam composts, typified by John Innes composts, are based on loam sterilized to eliminate the soil-borne fungi (see damping off) and insects that largely caused the unreliable results from traditional composts. There is a risk of ammonia toxicity developing after sterilization of soil with pH greater than 6.5 or very high in organic matter (see nitrogen cycle). Induced nutrient deficiencies are possible in soils with a pH greater than 6.5 or less than 5.5. Furthermore, loam should have sufficient clay and organic matter present to give good structural stability (the original specification identifies ‘turfy clay loam’). Peat and sand are added to further improve the physical conditions: the peat gives a high water-holding capacity and the coarse sand ensures free drainage and therefore good aeration. There are two main John Innes composts, one for seed sowing and cuttings, the other for potting. John Innes seed compost consists of 2 parts loam, 1 part peat and 1 part sand by volume. Well-drained turfy clay loam low in nutrients and with a pH between 5.8 and 6.5; undecomposed peat graded 3 mm to 10 mm with a pH between 3.5 and 5.0; and lime-free sand graded 1–3 mm should be used. 1200 g of superphosphate and 600 g of calcium carbonate (lime) are added to each cubic metre of compost. John Innes potting (JIP) composts consist of 7 parts by volume turfy clay loam, 3 parts peat and 2 parts sand. To allow for the changing nutritional requirements of a growing plant, the nutrient level is adjusted by adding appropriate quantities of JI base fertilizer which consists of 2 parts by volume hoof and horn, 2 parts superphosphate and 1 part potassium sulphate. To prepare JIP 1, 3 kg JI Base fertilizer and 600 g of calcium carbonate are added to one cubic metre of compost. To prepare JIP 2 and JIP 3, double and treble fertilizer levels respectively are used. Whilst the standard JI composts are suitable for a wide range of species, some modification is required for some specialized plants. For example, calcifuge plants such as Ericas and Rhododendrons should be grown in a JI(S) mix in which sulphur is used instead of calcium carbonate. All loam-based composts should be made up from components of known characteristics and according to the specification given. Such composts are well proven and are relatively easy to manage because of the waterabsorbing and nutrient-retention properties of the clay present. These composts are commonly used by amateurs, for valuable specimens, and for tall plants where pot stability is important; but loam-based composts have been superseded in horticulture generally by cheaper alternatives. The main disadvantage of loam-based composts has always been the difficulty of obtaining suitable quality loam (‘turfy clay loam’), as well as the high costs associated with steam sterilizing. Furthermore, the loam must be stored dry before use and the composts are heavy and difficult to handle in large quantities. Many of the loambased composts currently produced have relatively low loam content and consequently exhibit few of its advantages. Loamless or soilless composts Loamless composts introduced the advantages of a uniform growing medium, but with components that are lighter, cleaner to handle, cheaper to prepare and which do not need to be sterilized (unless being used more than once). Many have low nutrient levels which enable growers to manipulate plant growth more precisely through nutrition, but the control of nutrients is more critical, as many components have a low buffering capacity. Peat has until recently been the basis of most loamless composts. It is used alone or in combination with materials, such as sand, to produce the required rooting environment. Peats are derived from partially decomposed plants and their characteristics depend on the plant species and the conditions in which they are formed (see Soil organic matter). Peats vary and respond differently to herbicides, growth regulators and lime. All peats have a high cation exchange capacity, which gives them some buffering capacity. The less decomposed sphagnum peats have a desirable open structure for making composts and all peats have high water-holding capacities. Alternatives to peat Whilst peat remains a popular choice as a compost ingredient, great efforts are being made to find alternatives in order to preserve the wetland habitats where peat is harvested. A list of some of the materials used is given in Table 22.1. Much progress has been made by using suitably processed bark or coconut fibre in composts.

Where possible an environmentally friendly alternative is used, but there is considerable debate about the relative merits of some of those being used because of the associated energy use in their manufacture or transport. However, peat is being replaced successfully by different substitutes, many only available locally, according to the needs of the various sectors of the industry. Sand, grit or gravel is used in composts, frequently in combination with peat. They have no effect on the nutrient properties of composts except by diluting other materials. They are used to change physical properties. As sand or gravel is added to lightweight materials the density of the compost can be increased, which is important for ballast when tall plants are grown in plastic pots. Sand is also used as an inert medium in aggregate culture. Sand should be introduced with caution because it tends to reduce the air-filled porosity (AFP) of the final mix. It is important that the sands used should have low lime levels; otherwise they may induce a high pH and associated mineral deficiencies (see trace elements). Pulverized bark has been used as a mulch and soil conditioner for many years. More recently it has been tried in compost mixtures as a replacement for peat. There are many different types of bark and they have different properties. Its problems include the presence of toxics, overcome by composting, and a tendency to ‘lock-up’ nitrogen (see carbon to nitrogen ratio), which can be offset by extra nitrogen in the feed. When composted with sewage sludge, a material suitable as a plant-growing medium is produced. It is increasingly being incorporated into growing mixes in the attempt to reduce the use of peat. However, the great variation of barks, especially when they are from a mixed source, makes it difficult to incorporate into growing mixes. Much of the conifer bark tends to be stringy. Consequently the main role of bark is in mulching. The import of bark is strictly controlled by the Forestry Commission to prevent the introduction of pests and diseases. Wood-fibres based on stabilized shredded wood are being used to increase the air-filled porosity of mixes, but they tend to be dusty and not easily dispersed in compost mixes. Sawdust and off-cuts from the chipboard industry are also being tested for use in growing, but there are problems associated with their stability and fungal growth in the freshly stored material. Coconut wastes such as coir (the dust particles) are proving to be useful in growing mixes. The material has good water-holding capacity, rewetting and air-filled porosity characteristics. It has a pH between 5 and 6, which makes it suitable for a wide range of plants, but it cannot replace peat directly in mixes for calcifuges. It has a carbon:nitrogen ratio of 80:1 which means that allowance has to be made for its tendency to ‘lock-up’ nitrogen.

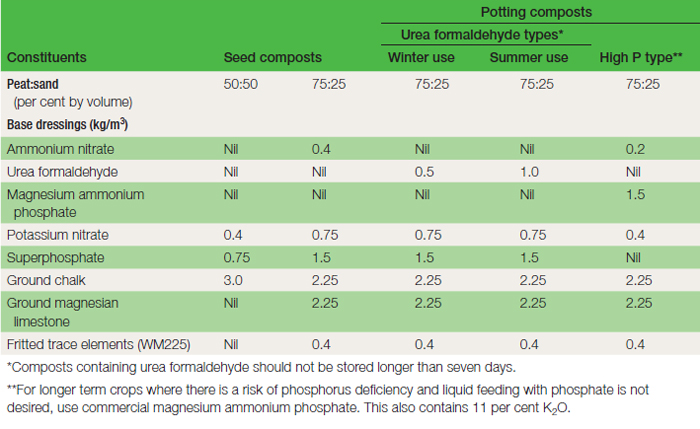

Vermiculite is a mica-like mineral expanded to twenty times its original size by rapid conversion to steam of its water content. The finished product is available in several grades, all of which produce growing media with good aeration and water-holding properties (see Figure 22.3). There is a tendency for the honeycomb structure to break down and go ‘soggy’. Consequently, for long-term planting, it tends to be used in mixtures with the more stable peat or perlite. Some vermiculites are alkaline, but the slightly acid samples are preferred in horticulture. Vermiculite has a high cation exchange capacity, which makes it particularly useful for propagation mixes. Most samples contain some available potassium and magnesium. Rockwool is an insulation material derived from a granitelike rock crushed, melted, and spun into threads. The resulting slabs of lightweight, spongy, absorbent, inert and sterile rockwool provide ideal rooting conditions with high water-holding capacity and good aeration. Shredded rockwool can be used in compost mixes (see Figure 22.3). Its pH is high but is easily reduced by watering with a slightly acid nutrient solution. It is frequently used in tomato and cucumber production and film-wrapped cubes are available for plant raising and pot plants. It is necessary to use a complete nutrient feed (see aggregate culture). It has some buffering capacity, but this is very low on a volume basis. The main problem areas lie in calcium and phosphorus supply and the control of pH and salt concentration. Some rockwool has been formulated with clay to overcome some of these problems. This increases its cation exchange properties, making it very suitable for interior landscaping. Rockwool is also available in water-absorbent and water-repelling forms. Mixtures of these enable formulators to achieve the right balance between airfilled porosity, water-holding and capillary lift. Rockwool is available as granules that provide a flexible alternative for those who produce their own mixes. However, it is most usually supplied as wrapped slabs, cubes, propagation blocks and plugs that are modularized to create a complete growing system. Pumice is a porous volcanic rock that is prepared for use as a growing medium by crushing, washing (to remove salt and ‘fines’) and grading. It is most commonly used to grow long-term crops such as carnations in troughs or polysacks. Expanded polystyrene balls or flakes provide a very lightweight inert material, which can be added to soils or composts as a physical conditioner. It is non-porous and so reduces the water-holding capacity of the growing medium while increasing its aeration, thus making it less liable to waterlogging when over-watered. This has made it an attractive option for winter propagation mixes. However, it is less popular than it might be because it is easily blown away and sticks to most surfaces. Plastic foams of several different types are becoming popular for propagation because of their open porous structure. They are available as flakes and balls for addition to composts or as cubes into which the cuttings can be pushed. Chopped straw has been used with some success. Generally the main types available, wheat and barley, break down too easily and a practicable method of stabilizing them has not yet been found. Stable, friable material has been derived from bean and oil seed rape straws, although care is needed in mixes because of the high potassium levels. Lignite is very variable soft brown coal formed from compressed vegetation; often found at the base of the larger peat bogs. The dusts, ‘fines’, have been used as carriers for fertilizers and the more granular material can be used to replace grit in mixes, often bringing an improved water retention. Absorbent polymers have the ability to hold vast quantities of water that is available to plants. However, this is considerably reduced in practice because water absorption falls as the salt concentration of the water increases and the release patterns appear to be very similar to that of some compost ingredients, such as sphagnum moss peats. Wetters, or non-phytotoxic detergents, are included in mixes to enable water to wet dry composts. They reduce the surface tension of the water, which improves its penetration of the pores. This speeds up the wetting process and maximizes the water-holding capacity of the materials used. Wetters should be selected with care because the different types need to be matched with the peat in the mix and above all must not be harmful to the plants. Compost mixes Materials alone or in combination are prepared and mixed to achieve a rooting environment that is free from pests and disease organisms and has adequate air-filled porosity, easily available water, and suitable bulk density for the plant to be grown. While lightweight mixes are usually advantageous, ‘heavier’ composts are sometimes formulated to give pot stability for taller specimens. This should not be achieved by compressing the lightweight compost, but by incorporating denser materials such as sand. Quick-growing plants are normally the aim and loosely filling containers with the correct compost formulation, consolidated with a presser board and settling it with applications of water obtain this. Firming with a rammer reduces the total pore space whilst increasing the amount of compost and nutrients in the container. The reduction in air-filled porosity and available water with an increase in soluble salt concentration leads to slower growing, harder plants (see conductivity). The addition of nutrients must take into account not only the plant requirements, but also the nutrient characteristics of the ingredients used. Most loamless composts require trace element supplements and many, including those based on peat, need the addition of all major nutrients and lime. The Glasshouse Crops Research Institute developed general purpose potting composts based on a peat/sand mix (see Table 22.2). They contain different combinations of nutrients and consequently their storage life differs. One of the range of composts has a slow release phosphate, removing the need for this element in a liquid feed (see phosphorus). The GCRI seed compost contains equal parts by volume of sphagnum peat and fine, lime-free sand. To each cubic metre of seed compost is added 0.75 kg of superphosphate, 0.4 kg potassium nitrate and 3.0 kg calcium carbonate. Variations on these mixtures are formulated with alternatives to peat, taking into account their different properties particularly with regard to their particle size, water-holding capacity and final air-filled porosity.

Compost mixing It is most important when making up the desired compost formulation to achieve a uniform product and, commercially, it must be undertaken with a minimum labour input. The ingredients of the compost must be as near as possible to the specification for the chosen formulation. Materials must not be too moist when mixing because it then becomes impossible to achieve an even distribution of nutrients. There are several designs of compost mixer. Continuous mixers are usually employed by specialist compost mixing firms and require careful supervision to ensure a satisfactory product. Batch mixers of the ‘concrete mixer’ design are produced for a wide range of capacities to cover most nursery needs. Many of the bigger mixers have attachments which aid filling. Emptying equipment is often linked to automatic tray or pot-filling machines. Ingredients used in loamless composts or growing modules do not normally require partial sterilization unless they are being reused, but sterilizing equipment is certainly needed to prepare loams for inclusion in loam-based composts. Where steam is used it is injected through perforated pipes on a base plate and rises through the material being sterilized. In contrast a steam–air mixture injected from the top under an air-proof covering is forced downwards to escape through a permeable base. Storage of prepared composts should be avoided if possible and should not exceed three weeks if slow release fertilizers are incorporated. If nitrogen sources in the compost are mineralized, ammonium ions are produced followed by a steady increase in nitrates. These changes lead to a rise in compost pH followed by a fall. As nitrates increase, the salt concentration rises towards harmful levels (see conductivity). Peat-based composts can become infested during storage by sciarid flies. |

||||||||||||||||||||||||