Vegetable production

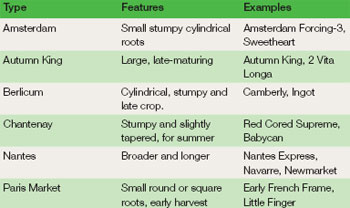

ContentThe choice of cultivar is an important decision that has to be made before growing starts. There are many possibilities for each crop, but a major consideration is the need for uniformity. Where this is important, e.g. for 'once over harvesting' or uniform size, then F1 hybrids are normally used even though they are more expensive. Required harvesting dates affect not only sowing dates but the selection of appropriate early, mid-season or late cultivars. Other factors for choice include size, shape, taste, cooking qualities, etc. Examples of carrot types to choose from are given in Table 1.1.

Most vegetables are grown in rows. This helps with many of the activities such as thinning and weed control. Seeds are often sown more thickly than is ideal for the full development of the plant; this ensures there are no gaps in the row and extra seedlings are removed before plant growth is affected. The final plant density depends on the crop concerned, but it is often adjusted to achieve specifi c market requirements, e.g. small carrots for canning require closer spacing than carrots grown for bunching. The arrangement of plants is also an important consideration in spacing ; equidistant planting can be achieved by offsetting the rows (see Figure 1.3). Seeds are often sown into a separate seedbed or into modular trays until they are big enough to be planted out, i.e. transplanted, into their fi nal position. This enables the main cropped areas to be used with a minimum of wasted space. It is also a means of extending the season and speeding up plant growth by the use of greater protection and, where worthwhile, with extra heat. Larger plants are better able to overcome initial pest or disease attack in the fi eld and also the risk of drying out.

Intercropping (the growing of one crop in between another) is uncommon in this country but worldwide is a commonly used technique for the following reasons:

Continuity of supply can be achieved by several means, most usually by the following:

Aftercare After the crop is established, there are many activities to be undertaken according to the crop, the production method and the intended market. These operations include:

The stage of harvesting is critical depending upon the purpose of the crop. Recognizing the correct stage to sever a plant from its roots will affect its shelf life, storage or suitability for a particular market. Some vegetables which are harvested at a very immature stage are called 'baby’ or 'mini'. The method of harvesting will vary; wholesale packaging requires more protective leaf left on than a pre-packed product. Grading may take place at harvesting, e.g. lettuce, or in a packing shed after storage, e.g. onions. Storage An understanding of the physiology of the vegetable or plant material being stored is necessary to achieve the best possible results. Root vegetables are normally biennial and naturally prepared to be overwintered, whether in a store or outside). Annual vegetables are actively respiring at the time of picking, but with the correct temperature and humidity conditions the useful life can be extended considerably. Great care must be taken with all produce to be stored as any bruising or physical damage can become progressive in the store. Dormant vegetables can be cold stored, but care must be taken to prevent drying out. For this reason different types of store are used depending on the crop; ambient air cooling is used for most hard vegetables and refrigeration for perishable crops gives a fast pull-down of temperature and field heat. |