Primary Metabolites

Vitamins

All phototrophic microorganisms are capable of synthesizing vitamins and other growth stimulating compounds for their vegetative growth by using the chemical constituents from the culture medium. When synthesis of these compounds exceeds beyond their requirement, it accumulates in cultures ; there from it is recovered. Now-a-days, commercial exploitation of such microorganisms is being done which synthesize vitamins on large scale under different cultural conditions. Micro-biologically produced some vitamins are : carotene, precursor of vitamin A (Blakeslea trispora), riboflavin (Ashbya gossypii), L-sarbose in vitamin C synthesis (Gluconobacter oxidans), and vitamin B12 (Bacillus coagulans, B. megaterium, Pseudomonas denitrificans and Streptomyces olivaceous).In nature, vitamin B12 is synthesized by microorganisms. For industrial production of vitamin B12 a number of bacteria and streptomycetes are used. The amount of vitamin B12 produced by them has been estimated about 20 mg/liter.

It is used in niedicine and feed supplements, and is most essential for human growth. Daily requirement of vitamin B12 is about 0.001 mg.

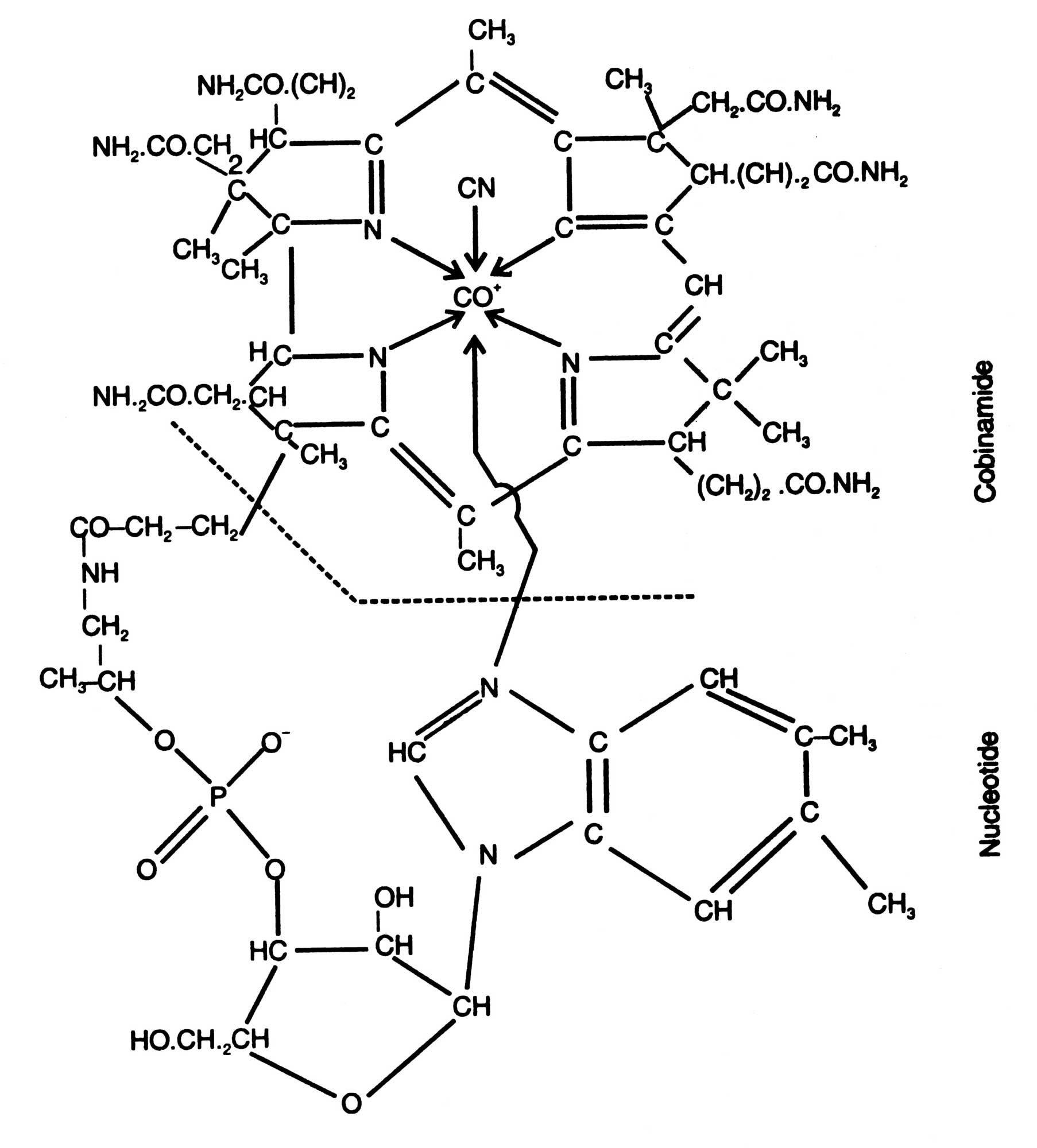

Chemical Structure

Vitamin B12 (cyanocobalamin) contains a molecule of cobinamide linked to a nucleotide which has 5,6-dimethyl benziminazole as its base, instead of a purine or pyrimidine base (Fig. 15.1). The cobinamide molecule has a central atom of cobalt linked to a cyanide group and surrounded by four reduced pyrol rings joined to form a macroring. A number of carbon atoms carry methyl or other substituent group (Riviere, 1977).

Commercial Production

Commercially vitamin B12 is produced in a continuous culture, where two fermenters are used in a series. In each fermenter culture is kept for about 60 hours. Precaution taken is that the first fermenter should be anaerobic, while the second aerobic one. In the second fermenter 5,6-dimethyl benziminazol is added continuously.

Sterilized culture medium, containing glucose, corn steep, betain (5%), cobalt (5 ppm) and pH 7.5 in fermenter, is inoculated with Propionibacterium freudenreichii and allowed to anaerobic fermentation for about 70 hours. During this period cobinamide is produced which accumulates in the broth. Thereafter, 5,6-dimethyl benziminazole (0.1%) is added to it. The fermenter is then kept further for 50 hours for aerobic fermentation.

During this period nucleotide is synthesized and linked with cobinamide molecule to yield about 20 ppm cobalamin. Culture is acidified to pH 2.0 to 3.0, gently heated to 100°C and filtered to remove cell debris. Finally potassium cyanide (5ppm) is added to filtrate to give cyanocobalamin. Generally sodium sulphite is mixed with the solution so that cyanocobalamin could not be oxidized.

Using genetic engineering techniques, it has become possible to obtain mutants of microorganisms, producing more vitamins than the natural ones. P. denitrificans is able to produce 50,000 times more vitamin B12 than its parental strain (Sasson, 1984).