Ex situ Bioremediation

Solid-phase Treatment

Solid-phase system includes organic wastes (e.g. leaves, animal manures and agricultural wastes), and problematic wastes (e.g. domestic and industrial wastes, sewage sludge and municipal solid wastes). The traditional clean-up practice involves the informal processing of the organic materials and production of composts which may be used as soil amendment.

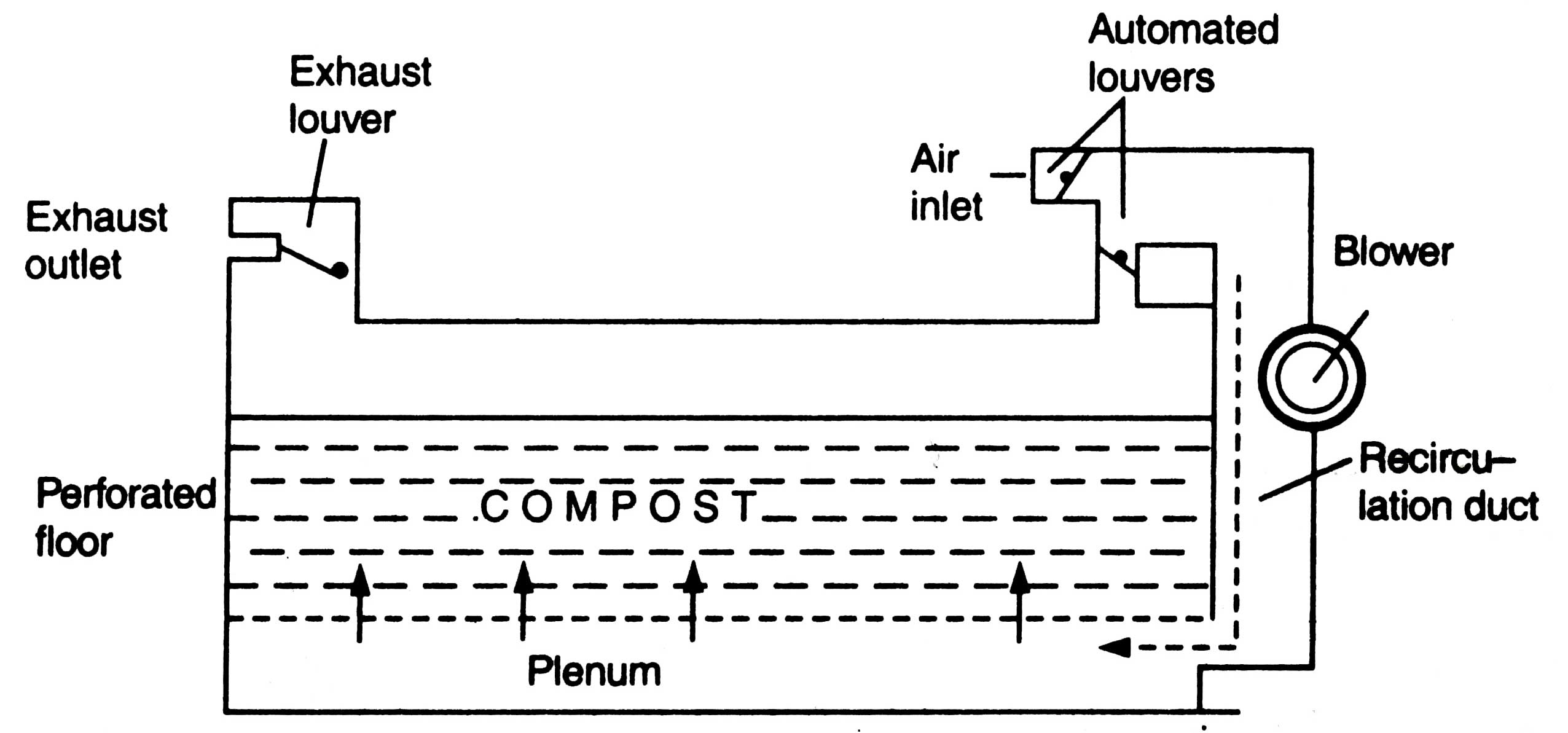

Fig. 21.3. Physical configuration of a closed composting system with forced ventilation (cutway side view) (based on Hogan 1998).

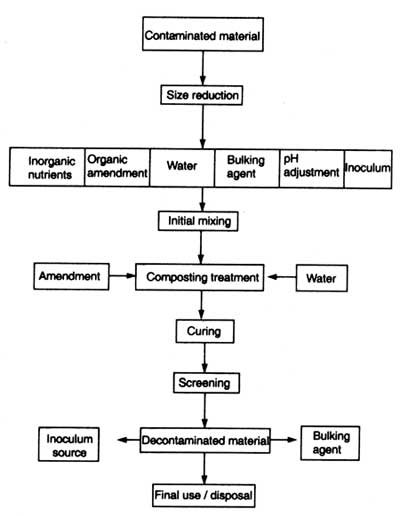

(ii) Composting Process. As composting is a solid-phase biological treatment, target compounds must be either solid or a liquid associated with a solid matrix. The hazardous compounds should be biologically transformed. To achieve this goal, the waste material should be suitably prepared so that biological treatment potential should maximize. This is done by adjustment of several physical, chemical and biological factors (Fig. 21.4). The hazardous wastes must be well solubilized so that they may be bioavailable. The hazardous compounds and soil organic matters serve the source of carbon and energy for microorganisms. Microbial enzymes secreted during growth phase degrade toxic compounds.

If there is low substrate-density or site-specific conditions, analogue or non-analogue, non-hazardous carbon sources that can stimulate microbial growth and enzyme production can be added to compost. Organic amendment also stabilize microbial population in inhibitory environment. Secondly, presence of sufficient amount of water enhances microbial growth. Addition of inorganic nutrients influences microbial growth and rate of decomposition of hazardous wastes. Under nitrogen limiting conditions Phanerochaete chrysosporium produces extracellular lignin peroxidase that degrades benzopyrene and 2,4,6-trinitrotoluene.

It has also been noted that a pH range of 5.0-7.8 promoted the highest rates of degradation of hazardous wastes. But lignin degradation has been found the most rapid at pH of 3.0-6.5. This shows that optimal pH levels can be species, site and waste specific.

Gradual colonization of organic materials is done by indigenous microflora, but hazardous chemicals may inhibit microbial growth. Therefore, bioaugmentation (i.e. use of commercial or GEMs) of wastes is also recommended.

To provide experimental proof of biodegradation during composting, a common hazardous contaminant pesticide, 14C-labelled Carbaryl was added in sewage sludge-wood chip mixture at 1.3 - 2.2 ppm concentration. After 18-20 days in laboratory composting apparatus, 1.6 - 4.9 per cent of Carbaryl was recovered as 14CO2 and remaining bound to soil organic matter.

Slurry-phase Treatment

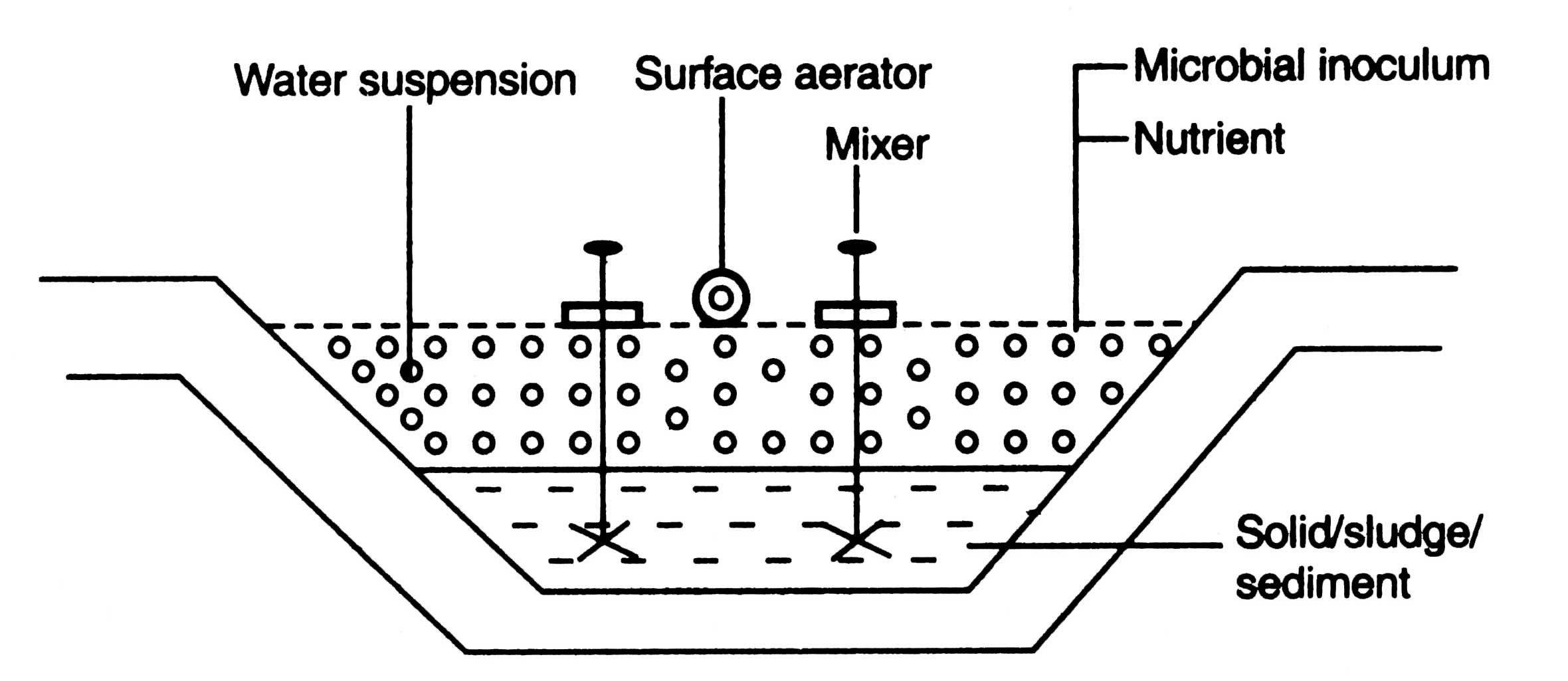

The contaminated solid materials (soil, degraded sediments, etc), microorganisms and water formulated into slurry are brought within a bioreactor i.e. fermenter. Thus slurry-phase treatment is a triphasic system involving three major components: water, suspended particulate matter and air. Here water serves as suspending medium where nutrients, trace elements, pH adjustment chemicals and desorbed contaminants are dissolved.

Biologically there are three types of slurry-phase bioreactors : aerated lagoons, low-shear airlift reactor, and fluidized-bed soil reactor. The first two types are in use of full scale bioremediation, while the third one is in developmental stage.

(ii) Low-shear Airlift Reactors (LSARs). The LSARs are useful when waste contains volatile components; tight process control and increased efficiency of bioreactors are required.

Fig. 21.6 shows a low-shear airlift slurry-phase bioreactor. LSARs are cylindrical tanks which is made up of stainless steel. In this bioreactor pH, temperature, nutrient addition, mixing and oxygen can be controlled as desired. Shaft is equipped with impellers. It is driven by motor set up at the top. The rake arms are connected with blades which is used for resuspension of coarse materials that tend to settle on the bottom of the bioreactor. Air diffusers are placed radially along the rake arm. Airlift provides to bottom circulation of contents in reactor. Baffles make the hydrodynamic behavior of slurry-phase bioreactors. Pre-treatment process includes size fractionation of solids, soil washing, milling to reduce particle size and slurry preparation. Certain surfactants such as anthracene, pyrene, perylene, etc. are added to enhance the rate of biodegradation. These act as co-substrate and utilize as carbon source. Co-substrates also induce the production of beneficial enzymes (Christodoultos and Kontsospyros, 1998).

Factors that affect slurry-phase biodegradation are

- pH (optimum 5.5-8.5),

- moisture content,

- temperature (20-30°C), oxygen (aerobic metabolism preferred),

- aging,

- mixing (mechanical and air mixing),

- nutrients (N, P and micronutrients),

- microbial population (naturally occurring microorganisms are satisfactory, genetically engineered microorganisms for layer compound may be added), and

- reactor operation (batch and continuous cultures).