Current Sources/Markets for Specialty Allyl/Propenyl Phenols

The major current source of allyl/propenyl phenols is clove oil, which generally

contains eugenol (

33, 75–85%), eugenyl acetate (35, 8–15%), and other minor

components. The oil is a product of the clove tree,

Syzygium aromaticum [

Eugenia

caryophyllata], and is mainly produced in Madagascar, Tanzania (Zanzibar and

Pemba Islands), as well as in Indonesia. Worldwide production of this oil approximates

2000 ton year

-1 (Bauer

et al., 2001), with a gross market value of approximately

US$ 30–US$ 70 million per annum through its applications in flavors,

fragrances, and antibacterials alone (George Uhe Company, 2006). This market

size is, however, largely dictated by (

1) the labor-intensive gathering of cloves,

(

2) the costs associated with obtaining the oil, and (

3) limited growth/production

capabilities. Therefore, a potential exists for the expansion of the source(s) of these

molecules through the use of new (bio)technologies.

Eugenol (

33) and its natural derivative, eugenyl acetate (

35), are widely used in

the perfumery and flavor industries, being considered by the Food and Drug

Administration (FDA) as Generally Recognized As Safe (‘‘GRAS’’) for use as food

additives. For example, eugenol (

33) is responsible for the majority of clove-like

flavors in beverages, ice cream, baked goods, and candy (Maralhas

et al., 2006),

whereas methyleugenol (

34) is a flavoring ingredient in ice cream, candy, and cola

soft drinks (Smith

et al., 2001; U.S. Environmental Protection Agency, 2006a).

Eugenol (

33) is also present in kretek (clove) cigarettes (usually as 40% ground

cloves, 60% tobacco) and is used as an industrial source of isoeugenol (

39) (by

alkaline isomerization) and methyleugenol (

34). Because of its excellent analgesic

and antibacterial properties, eugenol (

33) has long been employed in dentistry in

combination with zinc oxide forming a polymerized eugenol cement, which is

then used for surgical dressings, temporary fillings, pulp capping agents, and

cavity liners (Skinner, 1940; Weinberg

et al., 1972). Isoeugenol (

39) is widely used

as a flavor and fragrance additive in baked goods, beverages, chewing gum, and

personal products such as perfumes and soaps (Badger

et al., 2002). Isoeugenol

(

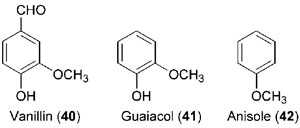

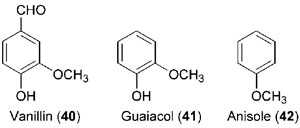

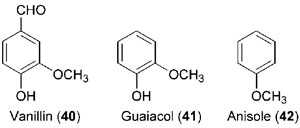

39) also used to be the main source for the industrial production of vanillin

(

40, Fig. 13.9), but the latter is now more commonly derived either from

the petrochemical guaiacol (

41) or from by-products of the pulp/paper (lignin)

industry (Hocking, 1997).

Chemically related products, anethole (

38) and methylchavicol (

32), on the

other hand, are currently isolated as minor by-products (1–2%) of crude sulfate

turpentine (CST) processing (The Flavor and Fragrance High Production Volume,

2002; 2005). This requires a lengthy isolation process of fractional distillation starting

from CST, and fractional crystallization from the semipurified terpenoid/phenolic mixtures thus produced.Most of themethylchavicol (

32) obtained in this way is then

subjected to alkaline isomerization to generate

|

| FIGURE 13.9 Structures of vanillin (40), guaiacol

(41), and anisole (42). |

more anethole (

38), although chemical

synthesis from anisole (42, Fig. 13.9) using propionyl chloride or propionaldehyde

can also be used. Although CST accounted for 97% of total turpentine

production in the United States in 1990, steadily increasing from 27.4% in 1950, the

total production of turpentine declined to approximately 20.7 million gallons in 1999

(Haneke, 2002) [containing an estimated 680 and 740 tons methylchavicol (

32) and

anethole (

38), respectively]. As wages increased, the labor-intensive production of

turpentine oil became increasingly less competitive economically, and thus much of

the original botanical-derived turpentine was substituted by cheaper petroleumbased

solvents in the intervening years.Anethole (38) finds application as a perfume

in detergents, soaps, and shampoos, and as a flavoring agent in licorice, ice cream,

baked goods, and alcoholic beverages (Newberne

et al., 1999), while methylchavicol

(

32) is added as a component of root beer and anise-type flavors, as well as condiments

and meat seasonings (The Flavor and Fragrance High Production Volume

Consortia, 2005).

Some allyl/propenyl phenols have also recently been approved by the Environmental

Protection Agency (EPA) for use as insecticides, insect repellents, and/

or insect lures, perhaps reflecting the original roles/functions of these natural

products

in planta. Applied as unmodified natural products, they have more

specific and less persistent insecticidal activities and therefore pose reduced

environmental risk relative to the commonly used organophosphates and pyrethroids.

Interestingly, eugenol (

33) is used as an insecticide not only for various

crop plants and ornamentals but also for pets (U.S. Environmental Protection

Agency, 2006b); furthermore, it can be used as an attractant in insect traps specific

for Japanese beetles (U.S. Environmental Protection Agency, 2006b,c). Anise oil,

on the other hand, is approved for use on lawns and ornamentals as a dog and cat

repellant (U.S. Environmental Protection Agency, 2006d), whereas methylchavicol

(

32), when applied to trees, repels bark beetles (for example, the southern pine

beetle) thereby limiting their aggregation and reproduction abilities (U.S.

Environmental Protection Agency, 2006e). Additionally, methyleugenol (

34) is

perhaps the most economically important allyl/propenyl phenol insect attractant,

being in widespread use in insect traps for certain fruit flies, including the

Oriental fruit fly, Mediterranean fruit fly, and solanaceous fly (Jang

et al., 2003;

U.S. Environmental Protection Agency, 2006a). (Fruit flies are one of the most

destructive pests to Hawaii’s agricultural industry, where these low-cost traps are

one of the few environment-friendly recommended suppression techniques.)