Potential for Allyl/Propenyl Phenols?

We consider that biotechnological approaches utilizing the enzymatic machinery

described above should now be explored to produce allyl and propenyl phenols,

diverting (to a predetermined extent) some of the carbon flow, for example, from

lignin toward these metabolites, while maintaining the resulting plants’ capacities

to grow and function within acceptable boundaries. The resulting cellulosic biomass

could thus become more amenable to pulp/paper manufacture and/or

biofuel production due to the lower lignin contents. Alternatively, oilseed metabolism

could be manipulated to produce these allyl/propenyl phenol substances

in larger amounts. Upon processing and purification, these compounds could

potentially find uses as biofuels, biofuel precursors, flavors/fragrances, and/or

intermediate chemicals (e.g., as monomers for synthetic polymers).

|

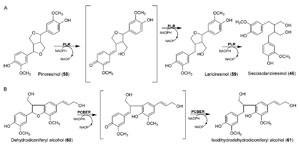

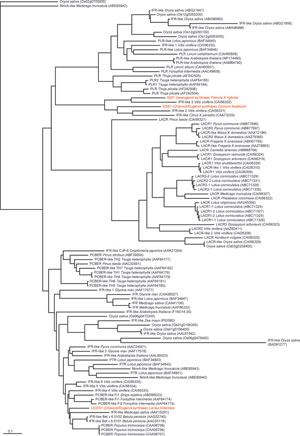

| FIGURE 13.17 Reactions catalyzed by

(A) PLR and (B) PCBER. |

Moreover, the ability to routinely biotechnologically modify plants and/or cell

cultures to produce allyl/propenyl phenols, such as chavicol (

31) and eugenol

(

33), now offers the opportunity to consider much larger markets for these products, that is, in addition to expanding the flavor/fragrance/antiseptic/biocidal

markets that currently exist (see above Section 3). For instance, in terms of

the flavor/fragrance market, the natural vanillin market can potentially be

expanded. Today, only about 0.2% of vanillin (

40, Fig. 13.9) used originates

directly from its botanical source, the vanilla bean, where it commands a sales

price of approximately US$ 4000 kg

-1 as a natural product. The bulk is semisynthetic,

being chemically synthesized either from the petrochemical-derived guaiacol

(

41) or from pulp/paper lignin-derivatives (i.e., technical lignins). However,

the vanillin (

40) produced in this way commands a price of only US$ 12 kg

-1 because it is not ‘‘natural.’’

Driven by consumer preferences toward truly ‘‘natural’’ food products, food

additives, and pharmaceuticals, several biocatalytic processes for production of

plant-derived metabolites using microbes and plant cell cultures have been developed

and patented in

|

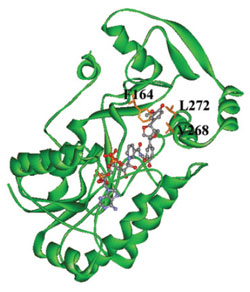

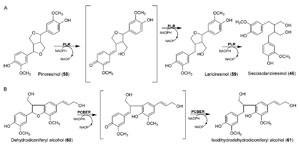

| FIGURE 13.18 Schematic representation

of the crystal structure of TpPLR1 with

NADPH and

(-)-pinoresinol (58).

Source: Reprinted from Min et al.

(2003). |

recent years (Berger, 1991; Krings and Berger, 1998; Longo

and Sanromán, 2006; Priefert

et al., 2001; Rabenhorst and Hopp, 1991; Schrader

et al., 2004; Shimoni

et al., 2000; Yoshimoto

et al., 1990). This enthusiasm has been

fueled by the promise to generate transgenic cultures with increased efficacy for

production of target metabolites. This approach also apparently offers economic

advantages over conventional chemical syntheses, including better stereospecificity

in product formation and lower amounts of waste products being generated

upon processing (Schoemaker

et al., 2003). In particular, production of flavors via

biotechnological processes offers an additional economic advantage since, unlike

their chemically prepared counterparts, the resulting products can be marketed as

‘‘natural’’ under current US and EU legislation (The European Commission, 1991;

Food and Drug Administration, 2006; Lesage-Meessen

et al., 1996; Shimoni

et al.,

2000). In this regard, successful microbial production of vanillin (40) from various

precursors, such as eugenol (

33) and isoeugenol (

39), has been reported recently,

being achieved at relatively high substrate concentrations (Krings and Berger,

1998; Longo and Sanroma´n, 2006; Priefert

et al., 2001; Rabenhorst and Hopp, 1991;

Schrader

et al., 2004; Shimoni

et al., 2000);

|

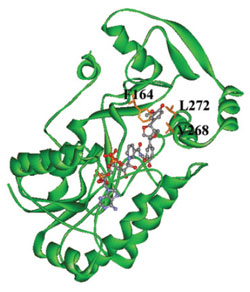

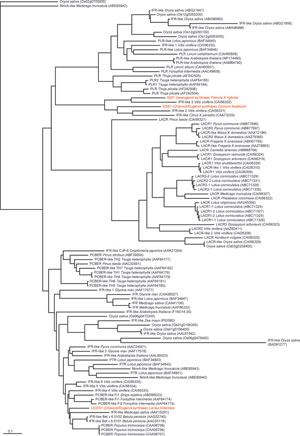

| FIGURE 13.19 Currently annotated phylogenetic

analysis of several PIp-reductase homologues

from different plant species, with relevant

homologues in basil (ObEGS1), petunia

(PhIGS1), and

creosote bush (LtCES1)

highlighted. IFR, isoflavone reductase; LACR,

leucoanthocyanidin reductase;

NmrA, nitrogen

metabolite repression regulator; PCBER,

phenylcoumaran-benzylic ether reductase;

PLR,

pinoresinol-lariciresinol reductase; PTR,

pterocarpan reductase. Sequences were

obtained

from the NCBI database and filtered for <0.75

sequence difference, ClustalW-aligned,

and

subjected to neighbor-joining phylogenetic

analysis using PHYLIP (Felsenstein, 1993). |

for example, transformation of

isoeugenol (

39) (20 g/L) using a strain of

Serratia marcescens led to vanillin (

40)

accumulation (3.8 g/L). An enzymatic process for conversion of isoeugenol (

39) into vanillin (

40) using a ligno stilbene-α,β-dioxygenase from a

Pseudomonas

paucimobilis strain has also been patented (Yoshimoto

et al., 1990). Thus, the

technologies are now apparently in hand to permit formation of natural vanillin

(

40) through established microbial and genetic manipulations in either plants

and/or plant/bacterial cell cultures.

Much larger anticipated potential markets for the allyl/propenyl phenols

include the industrial polymers and biofuel/biodiesel. Regarding polymer applications,

the expected worldwide production of polystyrenes alone was approximately

25 million metric tons in 2006, representing sales of US$ 31 billion. Allyl/

propenyl phenols can be converted into functionalized polystyrene derivatives,

and an increased supply creates the potential for their massive usage as intermediate

(monomer) chemicals in industrial polymers. Currently, existing applications

include eugenol- (

33) based polymers, which are widely used in dentistry in

zinc oxide impression pastes applied as surgical dressings and temporary

cements (Skinner, 1940; Weinberg

et al., 1972), as well as specialty modifying

(i.e., coating) agents in analytical electrodes (Ciszewski and Milczarek, 1998,

1999, 2001, 2003; Rahim

et al., 2004).

The functionalized β-methylstyrenes anethole (

38) and isoeugenol (

39) can be

converted into polymers of several thousand dalton (Bywater, 1963). However,

the potential of such conversions has been studied only to a limited extent relative

to their vinyl analogues (i.e., styrene and derivatives thereof), in part due to

limited supply/availability and because propenylbenzenes do not apparently

undergo as efficient free radical polymerization reactions as styrenes—even

though their electronic configuration is such that a radical intermediate can also

be stabilized by the aromatic ring (Alexander

et al., 1981). The most efficient

polymerization initiators described thus far for propenylbenzene derivatives are

Lewis acids, particularly AlCl

3, SnCl

4, and BF

3 (Alexander

et al., 1981; Cerrai

et al.,

1969a,b; Secci and Mameli, 1956).

In general, the steric factors on the monomers define, to a large extent, both

polymerization rates and molecular weights of the resulting polymers, with anethole

(

38), for example, being more reactive than isoeugenol (

39) (Alexander

et al.,

1981). Polymerization reactions can proceed through a conventional 1,2-chain

formation, similar to styrene, with the propagating species being a Lewis acidinduced

carbocation that is added to the double bond of another monomer.

This

results in a polymer backbone composed of the carbons 7 and 8 of the original

monomers. The molecular weights of the resulting polymers are higher at lower

temperatures and, in the case of anethole (

38) when polymerized by SnCl4, can

vary from a few thousand up to about 75,000 Da depending on both temperature

and dilution levels (Bywater, 1963; Cerrai

et al., 1969a; Secci and Mameli, 1956).

For isoeugenol (

39), the phenolic oxygen moiety also participates in the polymerization

reactions, thereby increasing the structural complexity of the resulting

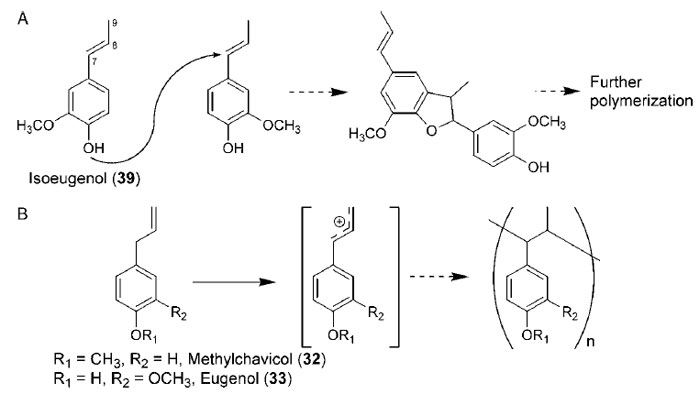

polymer(s) so formed (Fig. 13.20A) (Evliya and Olcay, 1974). Additionally, allylphenols,

such as methylchavicol (

32) and eugenol (

33), can form mixed polymers,

resulting from the partial rearrangement of the side-chain double bond upon

carbocation formation prior to attachment to the polymer chain (Cihaner

et al.,

2001; Kennedy, 1964) (Fig. 13.20B).

|

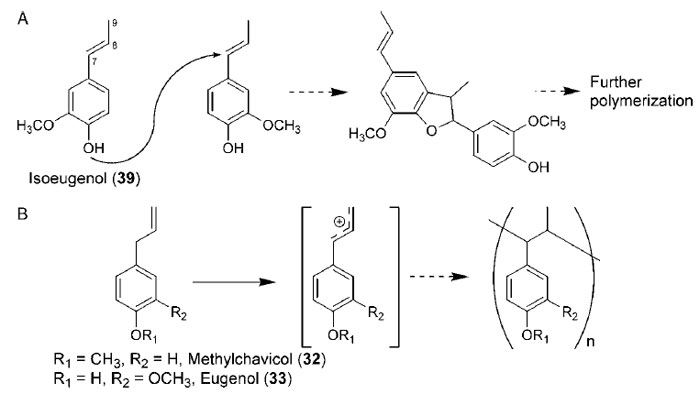

| FIGURE 13.20 Polymerization of (A) isoeugenol (39) via furanocoumaran intermediacy and

(B) methylchavicol

(32) and eugenol (33) through rearrangement prior to polymerization. |

In terms of their potential uses as biofuels, it is noteworthy that ~100 billion

gallons of gasoline fuel were consumed in the United States in 2005. In addition,

the annual consumption of diesel fuel in 2000, including highway diesel, farms,

electric power, railroad, fuel oil (residential, commercial, and heating), and kerosene,

totaled approximately 57.1 billion gallons. As a measure of the potential

scale of production of biodiesel (from vegetable oils, consisting mainly of fatty

acid esters), Peterson (1995) recently estimated that if

all harvested cropland (~363

million acres) in the United States was dedicated exclusively to rapeseed (oilseed)

production, then approximately 36.3 billion gallons (assuming 100 gallon/acre) of

vegetable oil could be obtained annually. [Note that at present there are approximately

27 billion gallons of vegetable oil produced worldwide annually (Peterson,

1995)]. Yields for other plant species, modified to concurrently synthesize chavicol

(

31), methylchavicol (

32), or eugenol (

33), now need to be determined to establish

to what extent these productivity numbers can be increased through (for instance)

whole plant utilization.

Additionally, if one considers the annual pulp and paper production in the

United States (~120 million metric tons/year, 1997 figures), the potential also

exists to divert some part of the production of lignins/heartwood lignans and

other phenylpropanoid derivatives in commercially important woody plant species

away from their natural biosynthetic pathways, that is, to afford allyl/propenyl

phenols, etc. In principle, the lignin/lignan substances currently produced

annually as by-products of pulp/paper industries (more than 50 million tons)

could instead be converted to approximately 15 billion gallons allyl/propenyl

phenols per annum, if fully converted. Nevertheless, any reduction in carbon

flow to lignin, or reductions/changes in heartwood-forming constituents, could

represent a significant increase in biofuel production.

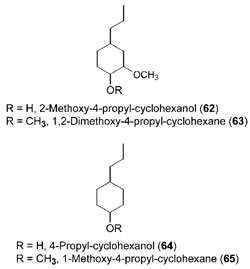

|

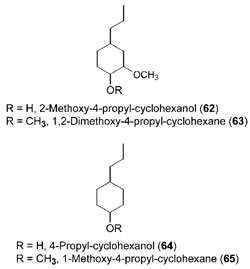

| FIGURE 13.21 Cyclohexane derivatives

formed upon catalytic hydrogenation of

the

corresponding allyl/propenyl phenols. |

Allyl and propenyl phenols have relatively high heats of combustion at room

temperature, with values generally being about 70% (per weight) of medium

chain hydrocarbons such as octane and decane. That is, these allyl/propenyl

phenols can potentially generate more energy (per weight) than ethanol. In

terms of other relevant properties, using two examples only for illustrative purposes,

chavicol (

31) has boiling/flash points of 238/102°C at normal atmospheric

pressure and density approximately 1.01 g/cm

3, whereas eugenol (

33) values are

approximately 253/112°C and 1.07 g/cm

3 (at 20°C). Such values are within the

ranges needed for biodiesel/biofuel considerations. Their reported freezing points

are, however, generally between –10°C and room temperature, which would

reduce their potential as liquid biofuels if used exclusively as such in pure liquid

form. This limitation might be circumvented, however, by either blending them

into other fuels, similar to the coconut oils added as biofuels to diesel in the

Philippines (BBC/PRI/WGBH The World, 2007) or through their chemical derivatization

to generate materials of lower freezing point prior to biofuel use (e.g.,

hydrogenation, which may also help reduce pollutant emission upon combustion).

Catalytic hydrogenation of side-chain double bonds of allyl/propenylbenzenes

is readily achieved at atmospheric pressures, whereas reduction of the

aromatic ring typically requires higher temperatures and pressures using traditional

metal catalysts (e.g., supported Pd or Raney Ni). Reduced allyl/propenyl

phenols have already been generated by such catalytic hydrogenation reactions;

for example, 2-methoxy-4-propyl-cyclohexanol (

62, Fig. 13.21) was obtained in

near-quantitative amounts from eugenol (

33) (Maillefer, 1990). Newer catalytic

systems, however, have the exciting potential to dramatically improve the

reduction conditions, for example, as recently reported for the quantitative hydrogenation of several benzene analogues, at room temperature and atmospheric

hydrogen pressure, using ruthenium-containing methylated cyclodextrin

catalysts (Nowicki

et al., 2006). Thus, this application of biotechnology, if further

explored/developed/applied, offers a potentially important new avenue for

sources of biofuels/bioenergy.