Solid-liquid extraction

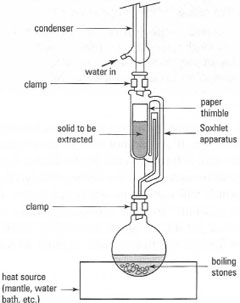

In this process the components of a solid mixture are extracted into a solvent. The 'batch process', analogous to liquid-liquid extraction, involves grinding the solid to a fine powder, mixing it with the appropriate solvent, and filtering off the solid by gravity or under vacuum and then evaporating the solvent from the extract solution. However, a more elegant 'continuous extraction process', called Soxhlet extraction, is available when the most appropriate solvent is known.The apparatus for Soxhlet extraction is shown in Fig. 14.5 and comprises a flask containing the solvent, a Soxhlet extractor and a reflux condenser. The solid to be extracted is placed in a porous thimble, made from hardened filter paper, and the solvent is heated so that its vapour flows past the thimble, condenses and fills the extractor with hot solvent to extract the solid. When the extractor is full, the solvent (together with the extracted material) siphons back into the solvent flask and the process is repeated automatically. The advantage of this procedure is that fresh solvent continually extracts the solid, which is concentrated in the flask.

The disadvantage is that the compound extracted is kept at the boiling point of the solvent for a prolonged period. Soxhlet extractors come in sizes of 10 mL to 5000 mL, based on the volume of solvent contained in the extractor. The procedure for using a Soxhlet extraction system is described in Box 14.2.

|

| Fig. 14.5 A Soxhlet extraction system. |