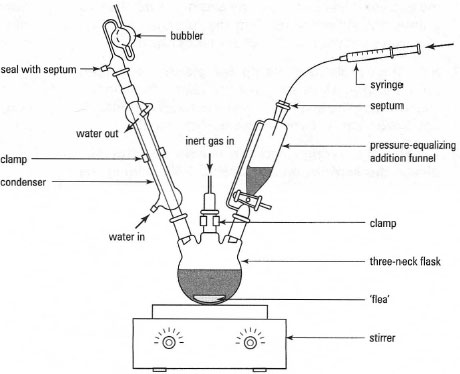

Syringe techniques

Many air-sensitive chemicals are supplied as solutions in nitrogen-filled bottles, which are sealed by a septum, and small volumes (up to 25 mL) of these solutions are best transferred to the apparatus using glass syringes. Similarly, air-sensitive liquids can be added to the reaction using a syringe.*Note: When removing air-sensitive reagents from nitrogenfilled bottles, you must replace the volume of liquid removed with inert gas (nitrogen) from a gas cylinder or balloon, via a needle, otherwise air (water, oxygen and carbon dioxide) will be pulled into the bottle as a result of the vacuum you have created.

Syringes

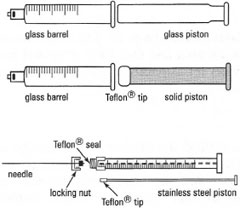

Glass, gas-tight syringes with a Luer lock fitting are the most versatile type of syringe and they come in a range of sizes. The Luer lock enables the stainless steel needle to be locked in place on the end of the syringe so that there is no danger of the needle dropping off the syringe during the transfer process (Fig. 18.3). Variations in syringe types include those with Teflon® -tipped pistons (plungers), which are somewhat more expensive.

Before using a syringe, always check that it is working by sucking up a little of the solvent to be used, ensuring that air is not sucked into the syringe either via the Luer lock or down a gap between the syringe and piston. If all is correct, disassemble the syringe and needle, dry in an oven at 120°C(not if Teflon® tipped) and allow to cool in a desiccator.

|

| Fig. 18.3 Syringes for inert atmosphere work. |

Once you have transferred the airsensitive reagent, you must clean out the syringe and needle immediately, by the appropriate method, as air will get into the needle and syringe and decompose the reagent causing the syringe to jam or the needle to block.

Needle-to-tubing connectors

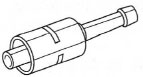

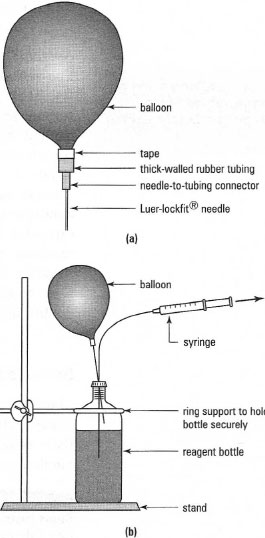

These adapters allow a Luer lock syringe needle to be connected to rubber tubing (Fig. 18.4). An inert gas supply can then be piped, via the needle, into a bottle to allow the transfer of large volumes of solvent or air-sensitive reagents to the apparatus. Alternatively a balloon can be taped to a short piece of thick-walled rubber pressure tubing to provide a supply of nitrogen when withdrawing air-sensitive reagents using a syringe (Fig. 18.5).

|

| Fig. 18.4 Needle-to-tubing connector. |

|

| Fig. 18.5 Inert atmosphere transfers: (a) balloon and needle; (b) preserving the inert atmosphere while removing reagent. |

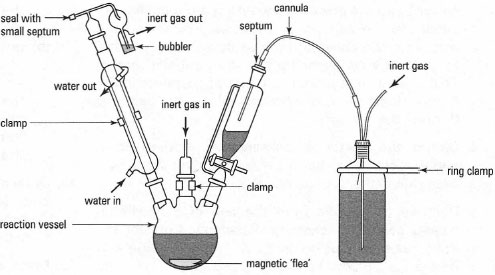

Stainless steel Luer lock syringe needles come in various lengths and diameters. The length of needle you will need depends on the size of the vessel from which you wish to withdraw the liquid; the diameter required depends on the size of the syringe - you should not use a large-diameter needle with a small-volume syringe - and the viscosity of the solution or liquid. Needle diameters are expressed in 'gauge': the higher the gauge, the narrower the needle diameter. For most inert atmosphere work you should use a needle with a 'non-coring' or 'deflecting' tip (Fig. 18.6), which ensures that a piece of the septum is not trapped in the needle when you push it through. Cannulae are long, flexible, double-ended needles made from stainless steel or inert plastics, which are used to transfer large volumes of reagents or solvents from one vessel to another under inert gas pressure (Fig. 18.7).

|

|

| Fig. 18.7 Transfer of air-sensitive reagents using the double-ended needle technique. | Fig. 18.6 Needle with non-coring tip for piercing septa, |

|

| Fig. 18.8 Transferring an air-sensitive reagent to a pressure-equalizing dropping funnel. |