Decomposition techniques for solid inorganic samples

Conversion of a solid matrix into a liquid matrix involves the decomposition of the sample. One of the major problems in preparing solid samples for trace element analysis is the potential risk of contamination. Contamination can arise from several sources: the grade of reagents used; the vessels used for digestion and the subsequent dilution of the sample; and human involvement.In order to minimize the risk of contamination you should take the following measures:

- Use the highest purity of reagents and acids, including the water used for sample dilution.

- Use sample blanks in the analytical procedure, to identify the base level of impurity in the reagents. Soak sample vessels in an acid leaching bath (e.g. 10% v]» nitric acid) for at least 24 hours, followed by rinsing in copious amounts of ultrapure water.

- Store cleaned volumetric flasks with their stoppers inserted; cover beakers with Clingfilm'P or store upside down to protect from dust.

- In addition to the wearing of a laboratory coat and safety glasses, it may be necessary to wear 'contaminant'-free gloves and a close-fitting hat.

Acid digestion

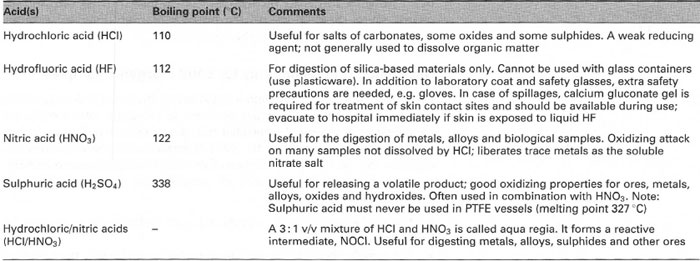

This involves the use of mineral or oxidizing acids and an external heat source to decompose the sample matrix. The choice of an individual acid or combination of acids depends upon the nature of the matrix to be decomposed. For example, the digestion of a matrix containing silica, SiO2 (e.g. a geological sample), requires the use of hydrofluoric acid (HF). A summary of the most common acids used for digestion and their application is shown in Table 27.3.

Once you have chosen an appropriate acid, place your sample into an appropriate vessel for the decomposition stage. Typical vessels include an open glass beaker or boiling tube for conventional heating or for microwave heating, a PTFE or Teflon® PFA (perfluoroalkoxyvinylether) vessel. A typical microwave system operates at 2.45 GHz with up to 14 sample vessels arranged on a rotating carousel; commercial systems have additional features such as: a PTFE-lined cavity; a safety vent (if the pressure inside a vessel is excessive the vent will open, allowing the contents to go to waste); and an ability to measure both the temperature and pressure inside the digestion vessels. The procedure for acid digestion of a sample is shown in Box 27.7.

|

| Table 27. 3 Common acids* used for digestion |

Other methods of sample decomposition

The use of acid(s) and heat is probably the most common approach to the decomposition of samples. However, several alternatives exist including dry ashing and fusion.

Dry ashing involves heating the sample in air in a muffle furnace at 400- 800°C to destroy the sample matrix, e.g. soil. After decomposition, the sample residue is dissolved in acid and quantitatively transferred to a volumetric flask prior to analysis. The method may lead to the loss of volatile elements, e.g. Hg, As.

Some substances, such as silicates and oxides, are not always destroyed by the direct action of acid and heat. In these situations an alternative approach is required. Fusion involves the addition of a lO-fold excess of a suitable reagent (e.g. lithium metaborate or tetraborate) to a finely ground sample. The mixture is placed in a metal crucible, e.g. Pt, and then heated in a muffle furnace at 90 – 1000°C. After heating (from several minutes to several hours) a clear 'melt' should result, indicating completeness of the decomposition. After cooling, the melt is dissolved in HF (Table 27.3). This process can lead to a higher risk of contamination.